Advanced Manufacturing Teaching Assistant

Spring 2025 I was a Teaching Assistant for the graduate-level course ME500: Advanced Manufacturing, Functional Materials and Automation.

Key Lab Topics

I guided students through hands-on labs within a state of the art flexible manufacturing cell that bridges the latest in robotics and manufacturing. My instruction focuses on 4 key modern manufacturing techniques:

CNC Milling

I teach students how to zero CNCs, use CAM software, fixture parts, and follow essential safety procedures. By the end of the semester, everyone knows machine their own parts indepedently.

Machine Tending

Machine tending uses robotic arms to automatically load and unload CNC machines. I teach students learn how to set robotic waypoints and program tasks using CIM (Computer Integrated Manufacturing) software.

.png)

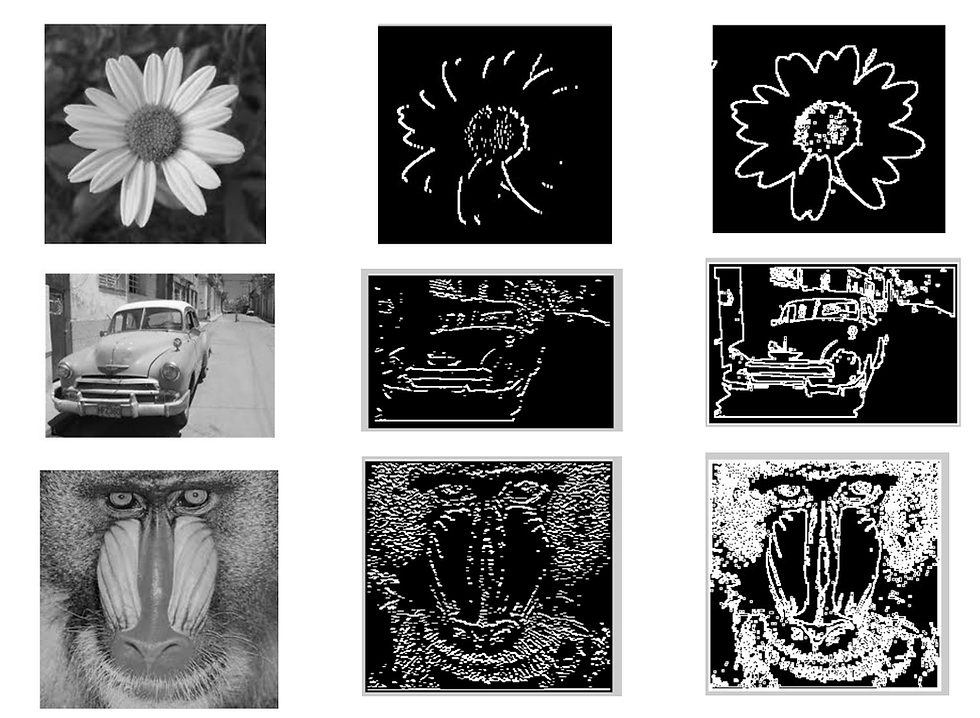

Computer Vision

Computer vision enables manufacturing defects to be automatically detected. It helps ensure product quality and consistency on production lines. I teach students how to use Teledyne-Dalsa Vision Systems

Metal Ink Printing

Students create a conductive silver ink using DOWSIL and XIAMETER. I teach how to properly mix the ink and apply all other aforementioned skills to fully automate the production of functional PCBs.

Various Photos of ADML

Lab Layout

The ADML is a mini Flexible Manufacturing Cell (FMC) located within the Engineering Product Innovation facility at BU.

It consists of two Haas CNC machines, three Universal Robotics Arms, all connected by a central conveyor belt system with carts for transporting parts between stations.

Parts are machined at Stations 3 and 4, while assembly occurs at Station 1. All actions are coordinated with a custom CIM script that controls the Robots, CNCs, and Carts.

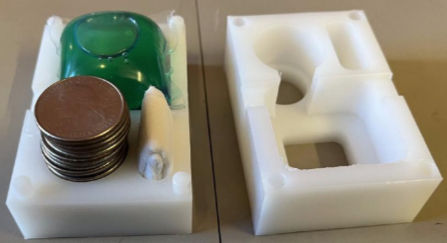

Student Projects

Throughout the semester, students work on team-based projects with the goal of designing and building a new product that positively impacts society. Projects must be manufactured automatically using Lab Resources. I actively consult with student groups during the design and manufacturing phases, offering ideas, technical feedback, and ensuring all designs adhere to DFM standards.